Piller Blowers in Sulfuric Acid Production

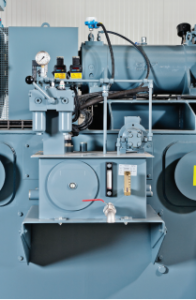

PILLER‘s unique blowers combine high efficiency with high performance. The consistent design starting from the casing over the impeller and shaft seal system to the patented bearings makes possible to use PILLER blowers in almost any applications where high pressure, high temperature or a combination of both is needed. Also corrosive products in the gas stream, combined with water are challenges that PILLER blowers are able to deal with.

As a byproduct of metal ore mining like FeS2, Cu2S or CuFeS2 the sulfur is separated and extracted. Sulfur dioxide SO2 is made by roasting the sulfide ores and oxygen (in the form of air) which combine to form sulfur trioxide in the presence of a catalyst. The PILLER blower provides the oxygen (air) for the process.

The PILLER blowers are replacing turbo compressors in these applications. Smaller investment, better efficiency, wide range of operation and lower maintenance are the main advantages, going along with higher reliability and easier operation.

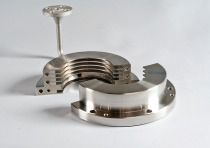

PILLER pays great attention to details like shaft seal and bearings in order to give the blower the highest reliability possible.

The high quality floating ring type shaft sealing, designed by Eagle Burgmann, ensures the tightness of the blowers where the shaft enters the blower casing. The shaft has a horizontal split which allows easy assembly and maintenance without disassembling the impeller.

The shaft sealing, like our blowers, can be customized according to the process conditions. The number of rings, buffer gas connection, vacuum suction, special alloys as well as other properties can be selected.